Showing Toyota’s historical car-making challenge and its current advanced technology of Toyota cars

Outline of Automobile Pavilion

Here, I’ll report on the exhibition of “Automobile Pavilion” in the

Here, I’ll report on the exhibition of “Automobile Pavilion” in the  Toyota Industrial Museum, following the last “Textile Pavilion.”. The “Automobile Pavilion” in the museum shows the Toyota’s historical development of technology and its initial business challenge, as well as its current conditions of automobile technology of

Toyota Industrial Museum, following the last “Textile Pavilion.”. The “Automobile Pavilion” in the museum shows the Toyota’s historical development of technology and its initial business challenge, as well as its current conditions of automobile technology of  Toyota. As we see the previous observation, Toyota was beginning to challenge to product automobiles using accumulated technology and capitals based on the textile machinery business from 1930s. The museum shows how Toyota could successfully transform its business from textile sector to automobile and how it expand its automobile technology and business to the current

Toyota. As we see the previous observation, Toyota was beginning to challenge to product automobiles using accumulated technology and capitals based on the textile machinery business from 1930s. The museum shows how Toyota could successfully transform its business from textile sector to automobile and how it expand its automobile technology and business to the current  outstanding great position in the historical views and extensive technological analysis.

outstanding great position in the historical views and extensive technological analysis.

The Pavilion is roughly divided into four major categories. That is, a history corner named “Challenge” for producing Toyota’s own passenger car, a corner of the “Technological development process” to show how automobile engine and component have been created, a corner of ” R&D system and strategy” for showing how it build-up automobile industry in the company”, and also illustrations what’s called  “Toyota Production System, TPS” in the production scene. Abundant exhibits related automobile technology and its structural features, evolution of production technology, in addition to the current machinery development are displayed in the Pavilion. Various historical anecdotes regarding Toyota’s technology development also introduced here.

“Toyota Production System, TPS” in the production scene. Abundant exhibits related automobile technology and its structural features, evolution of production technology, in addition to the current machinery development are displayed in the Pavilion. Various historical anecdotes regarding Toyota’s technology development also introduced here.

See: Toyota Industrial Technology Museum Automobile PavilionHP: http://www.tcmit.org/exhibition/car/

♣ Technological challenges of Toyota’s automotive business

<Toyota’s initial Challenge to automobile business >

In this section, the exhibition shows how Kiichiro Toyoda (a son of founder of Toyoda Sakichi), has started the challenging business of automobile succeeding textile machinery industry by using keywords “Determination”, “Challenge “ and “Leap Forward.

In this section, the exhibition shows how Kiichiro Toyoda (a son of founder of Toyoda Sakichi), has started the challenging business of automobile succeeding textile machinery industry by using keywords “Determination”, “Challenge “ and “Leap Forward.

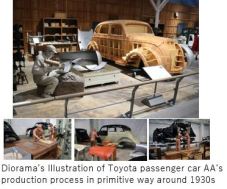

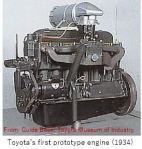

In the beginning for his challenge, Kiichiro set up “Automotive Department” inside the “Toyoda Automatic Loom Works” (a predecessor of Toyota Co.) in 1933, and he put forward to a trial work of automobile production with it. Then, he firstly set up a “material testing room” and “steelmaking section” in the company for producing iron materials for automobile parts and body by their  own hand. At this department, the engine blocks for vehicle were tried to make, but it was not easy task at that time. They faced so many difficulties because the high-level casting technology to create enough resilience to the machines, like engine block, had been existed in Japan at that time.

own hand. At this department, the engine blocks for vehicle were tried to make, but it was not easy task at that time. They faced so many difficulties because the high-level casting technology to create enough resilience to the machines, like engine block, had been existed in Japan at that time.

At the exhibition, the old machinery that used in the trial period is placed in the “Test room” in the pavilion. Solid model of casting cylinder blocks there gives lively images of the process of trial and error that time. And Toyota’s first “A type engine” and other type of initial engine models are also displayed there. These exhibits remind us the actual image of the Toyota’s “Challenge” time and its tireless efforts those days. The outcome from these continuous efforts was actually the “Type A prototype passenger car” (completed in 1935).  This memorial car is proudly exhibited in the pavilion along with various metal sheets of body, assembled reproduction models, and other components produced at that time. And in 1936, the company finally completed its marketable first passenger car. This vehicle is exhibited in this corner too. It was the time when the company has changed its name from “Toyoda” to “Toyota” and has entered the full-scale automobile business industry in 1937.

This memorial car is proudly exhibited in the pavilion along with various metal sheets of body, assembled reproduction models, and other components produced at that time. And in 1936, the company finally completed its marketable first passenger car. This vehicle is exhibited in this corner too. It was the time when the company has changed its name from “Toyoda” to “Toyota” and has entered the full-scale automobile business industry in 1937.

<Road to full-scale car production and its marketing>

Toyota wanted to start full-scale production of automobiles from the initial period with seeing huge potentials in the domestic

Toyota wanted to start full-scale production of automobiles from the initial period with seeing huge potentials in the domestic  market, but the true challenge was how to achieve the affordable price to set in production and how to build enough supply chains to meet consumer demand. In order to respond to the requirement, Toyota built the modern “Korom Plant” in Sakae region, Nagoya (1938) for starting the integrated production site of automobiles. There’s an anecdote story in the museum that the concept of “just-in-time” had been initially adopted in the factory.

market, but the true challenge was how to achieve the affordable price to set in production and how to build enough supply chains to meet consumer demand. In order to respond to the requirement, Toyota built the modern “Korom Plant” in Sakae region, Nagoya (1938) for starting the integrated production site of automobiles. There’s an anecdote story in the museum that the concept of “just-in-time” had been initially adopted in the factory.

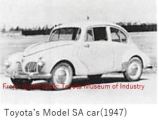

However, production and sales of automobiles were interrupted by the Pacific War, and the War time destruction, then the start of full-scale car production had to wait for the postwar period. Although Toyota suffered from severe business crisis after the War, the company embarked on

However, production and sales of automobiles were interrupted by the Pacific War, and the War time destruction, then the start of full-scale car production had to wait for the postwar period. Although Toyota suffered from severe business crisis after the War, the company embarked on  reconstruction of automobiles business immediately, and Toyota has challenged to produce small passenger car “SA type” and small truck “SB type” in 1947 responding to the strong market demand. Then, in 1955, the first full-scale domestic passenger car “Toyopet Crown” was born, These model memorial cars is on display in the pavilion and now charm visitors.

reconstruction of automobiles business immediately, and Toyota has challenged to produce small passenger car “SA type” and small truck “SB type” in 1947 responding to the strong market demand. Then, in 1955, the first full-scale domestic passenger car “Toyopet Crown” was born, These model memorial cars is on display in the pavilion and now charm visitors.

♣ Exhibition of the transition toward full-scale car

This next corner tries to exhibit the transition of its technological development of Toyota’s automobile, specifically on the features of

This next corner tries to exhibit the transition of its technological development of Toyota’s automobile, specifically on the features of  automobile parts embodied, its functions and structure, in addition to the driving systems consisting vehicles. For examples, showing the mechanism of the engine, transmission, brake, steering, chassis and body, and others by the real models or cut models. Also there’s an explain in detail about what kind of functions the parts have, and what kind of technology has been used

automobile parts embodied, its functions and structure, in addition to the driving systems consisting vehicles. For examples, showing the mechanism of the engine, transmission, brake, steering, chassis and body, and others by the real models or cut models. Also there’s an explain in detail about what kind of functions the parts have, and what kind of technology has been used

to make it.

to make it.

For example, in the case of showing engines, 14 representative Toyota engines are displayed side by side, so that the evolvement of engine technology can be observed clearly there. The evolution of transmission system is also on display with exemplifying 7 units of them, first from the Crown’s 3-speed manual transmission to the

latest automatic transmission with electronic control.

latest automatic transmission with electronic control.

Regarding the driving system and suspension of cars, the specimen models are exhibited to indicate the transition of the mechanism with using model vehicles, like the first generation of Crown, Corolla and Celsior, FF Camry, and Landcruiser for the 4WD system. By looking at this exhibition,  visitors could recognize the characteristics of driving system and its running stability as well as the development direction automaker Toyota has been aiming at. The steering and braking systems are also extensively introduced. So, visitors could learn well about the complicated mechanism of power steering, the principle of ABS, etc. by seeing devices which installed in the model cars.

visitors could recognize the characteristics of driving system and its running stability as well as the development direction automaker Toyota has been aiming at. The steering and braking systems are also extensively introduced. So, visitors could learn well about the complicated mechanism of power steering, the principle of ABS, etc. by seeing devices which installed in the model cars.

♣ Exhibition on the footprint of Toyota’s technology development

In this section, the footsteps of Toyota’s automobile development technology are described, by showing the typical model cars of Toyota produced in the past decades. It characterizes the broad range of technological advancement comparing the past and present. For the examples, improvement of materials to use for vehicles,

In this section, the footsteps of Toyota’s automobile development technology are described, by showing the typical model cars of Toyota produced in the past decades. It characterizes the broad range of technological advancement comparing the past and present. For the examples, improvement of materials to use for vehicles,  designing skills, structural scale-up, and driving conformity and fuel efficiency, so on. We can see that the line-up of Toyota’s representative leading cars there, such as variety models from 1930s, the current modern vehicles equipped with advanced functions, to the futuristic model car “Mirai” and other advanced cars. Among them we can find the legendary

designing skills, structural scale-up, and driving conformity and fuel efficiency, so on. We can see that the line-up of Toyota’s representative leading cars there, such as variety models from 1930s, the current modern vehicles equipped with advanced functions, to the futuristic model car “Mirai” and other advanced cars. Among them we can find the legendary  “Toyoda AA” passenger car in 1936, and the epoch-making first model car of “Toyota Crown” in 1955 and other cars.

“Toyoda AA” passenger car in 1936, and the epoch-making first model car of “Toyota Crown” in 1955 and other cars.

It is also interesting to see the transition of technology to respond the consumers’ preference and social requirement. For example, the challenges to safety and environment since 1970s and 1980s, and o the current stage of seeking designing, driving conformity and safety.  So, in this corner, the museum is introducing various functions embodied by displaying many real cars, such as the first Corolla (1966), Corona general (1973), Camry (1982), Celsior (1989), and the recent “Prius” (1997). There is also a clear explanation of PHV (2012) system and introduction of Toyota hybrid system in detail.

So, in this corner, the museum is introducing various functions embodied by displaying many real cars, such as the first Corolla (1966), Corona general (1973), Camry (1982), Celsior (1989), and the recent “Prius” (1997). There is also a clear explanation of PHV (2012) system and introduction of Toyota hybrid system in detail.

♣ Reproducing exhibition of automobile assembly line

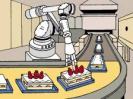

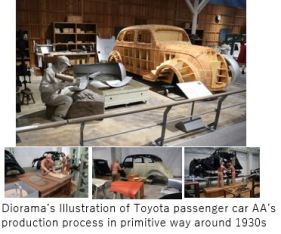

This section provides the reappearance of image map of Toyota’s first automobile factory, named Koromo works in Aichi prefecture, where the company has fully started producing cars with adopting new systematic assembly line in the 1930s. It reproduces the image of the production process of Toyota’s AA passenger,

This section provides the reappearance of image map of Toyota’s first automobile factory, named Koromo works in Aichi prefecture, where the company has fully started producing cars with adopting new systematic assembly line in the 1930s. It reproduces the image of the production process of Toyota’s AA passenger,  showing how perform casting, forging, machining, pressing, painting and assembly works. In addition to this, the exhibition tries to evaluate the advancement of production technology from the initial stage to the latest one, so you can check how the production line and processing technology have progressed in the 50 years. This seems one of the highlights of the automobile pavilion too.

showing how perform casting, forging, machining, pressing, painting and assembly works. In addition to this, the exhibition tries to evaluate the advancement of production technology from the initial stage to the latest one, so you can check how the production line and processing technology have progressed in the 50 years. This seems one of the highlights of the automobile pavilion too.

<Exhibition of automobile production lines>

This section features the situation of assembly line of “Toyota’s AA” car. The body making, fender processing, engine block casting, machining, etc. are all displayed here along with the overall configuration of the factory map in the 1930s. And the technology advancement in the press works, machine processing, and other big transfer machines are also lively facilitated.

This section features the situation of assembly line of “Toyota’s AA” car. The body making, fender processing, engine block casting, machining, etc. are all displayed here along with the overall configuration of the factory map in the 1930s. And the technology advancement in the press works, machine processing, and other big transfer machines are also lively facilitated.

<Reproducing scene of casting and forging, machining process>

In this section, the transition of casting technology is displayed in addition to the scene of Toyota’s former Koromo factory in Nagoya. First of all, it shows the casting process of engine, cylinder and block in the 1930s and 40s, beside the explanation of advanced casting technology and its machines, like automatic high-speed high-pressure shaping system, aluminum alloy’s high-pressure casting technology, alloy die-casting method, and other machinery technology..

In this section, the transition of casting technology is displayed in addition to the scene of Toyota’s former Koromo factory in Nagoya. First of all, it shows the casting process of engine, cylinder and block in the 1930s and 40s, beside the explanation of advanced casting technology and its machines, like automatic high-speed high-pressure shaping system, aluminum alloy’s high-pressure casting technology, alloy die-casting method, and other machinery technology..

The evolution of forging process is explained in detail here, particularly on the forging works of gears and steering parts. It also exhibits how the large-sized automatic press of current using 6000 ton’s press works along with comparatively showing the hand-made forging process in the early

The evolution of forging process is explained in detail here, particularly on the forging works of gears and steering parts. It also exhibits how the large-sized automatic press of current using 6000 ton’s press works along with comparatively showing the hand-made forging process in the early

1940s. So this exhibition indicates what sort of change has been occurred in the forging working process. Then, we can confirm the technological advancement that has been achieved in machining regarding accuracy and speed with observe the exhibits, especially on the improvement of quality of engine parts. The improved equipment includes the

1940s. So this exhibition indicates what sort of change has been occurred in the forging working process. Then, we can confirm the technological advancement that has been achieved in machining regarding accuracy and speed with observe the exhibits, especially on the improvement of quality of engine parts. The improved equipment includes the  crankshaft pin lathe (1964), the installation of a transfer machine (1969), and the Toyota’s joint drilling machine (1996), etc. The exhibition looks showing the real picture of how machining innovations have been accomplished in order to accommodate current automation and multi-variety production process.

crankshaft pin lathe (1964), the installation of a transfer machine (1969), and the Toyota’s joint drilling machine (1996), etc. The exhibition looks showing the real picture of how machining innovations have been accomplished in order to accommodate current automation and multi-variety production process.

<Dynamic display of vehicle installation and painting technology>

Here, we can see the dynamic models of the automatic welding assembly system that is adopted for Toyota’s recent vehicle production in the display. It can be noticed in the section how automated robots are operating in the assembling process. The exhibition also indicates how working process has been shifted from primitive manual sheet metal processing to the high-quality body-making in high speed and massive scale production by introduction of this innovative automation.

Here, we can see the dynamic models of the automatic welding assembly system that is adopted for Toyota’s recent vehicle production in the display. It can be noticed in the section how automated robots are operating in the assembling process. The exhibition also indicates how working process has been shifted from primitive manual sheet metal processing to the high-quality body-making in high speed and massive scale production by introduction of this innovative automation.

Painting technology has also evolved in the automatic work by robots now. In the exhibition, the technology of coating film which prevents rust on the vehicle’s surface and keeps smoothness of body are explained compactly. Actually the exhibition shows how huge technological advancement has been attained in the coating as well as the composition of paint materials from the manual work stage using simple brush tool in the beginning to the recent automatic high-tech spray operation.

The scene of moving assembly line of body mounting, automatic and baking process was really amazing. It is a spectacular sight that a number of body panels are transported to the assembly line by belt conveyor, and assembled and welded automatically one after another by the robot’s hands. Also, the painting process is similarly made by the automatic painting system using the electrostatic coating method. Furthermore, the body is sprayed in a sealed chamber, and there a dipping and electrodeposition coating is done automatically. There it is hardly found human involvement, and the entire works are completely performed only by electronic control system. The scene of smoothly carried out process there were really impressive.

The scene of moving assembly line of body mounting, automatic and baking process was really amazing. It is a spectacular sight that a number of body panels are transported to the assembly line by belt conveyor, and assembled and welded automatically one after another by the robot’s hands. Also, the painting process is similarly made by the automatic painting system using the electrostatic coating method. Furthermore, the body is sprayed in a sealed chamber, and there a dipping and electrodeposition coating is done automatically. There it is hardly found human involvement, and the entire works are completely performed only by electronic control system. The scene of smoothly carried out process there were really impressive.

<Dynamic exhibition of assembly line >

After the completion of body and painting, the works enter the final stage of automobile assembly line. This is the best place to inspect how the real car is going to

After the completion of body and painting, the works enter the final stage of automobile assembly line. This is the best place to inspect how the real car is going to  produce. The corner shows the real assembly lines remodeled at the Toyota’s Koromo factory. It also exhibits a dynamic visual movement of production scene, what’s called as “Toyota Production System” and “Just-in-time” scheme in the real site.

produce. The corner shows the real assembly lines remodeled at the Toyota’s Koromo factory. It also exhibits a dynamic visual movement of production scene, what’s called as “Toyota Production System” and “Just-in-time” scheme in the real site.

There, the chassis is attached to car body automatedly, then the various parts like engines, doors, tires and others are effectively installed, before exterior parts are smoothly furnished. It is said that an automobile unit would require to equip with an average of 20000 to 30000 parts for completion. It was a really great chance to directly observe this complicated process with our eyes in the real site.

♣ Exhibition of Toyota production method

It is sure that there’s many technical difficulties to automate and to effectively streamline the assembling

It is sure that there’s many technical difficulties to automate and to effectively streamline the assembling  process of a large number of parts which have complex shapes. In this requirement, it is indispensable to harmonize the mechanical movement with human works in production process, and it must ensure the reliability of working procedures in safe and accurately. In addition, it is crucial to have an effective

process of a large number of parts which have complex shapes. In this requirement, it is indispensable to harmonize the mechanical movement with human works in production process, and it must ensure the reliability of working procedures in safe and accurately. In addition, it is crucial to have an effective  system to supply various parts in the accurate timing as well as in the just volume. Thus, the “Toyota Production System” was first invented by Toyota Co. at the Koromo factory to respond these requirements. And this concept has widely distributed in the manufacturing field and rapidly became as an innovative system, not only automobile assembly factories, but other field too.

system to supply various parts in the accurate timing as well as in the just volume. Thus, the “Toyota Production System” was first invented by Toyota Co. at the Koromo factory to respond these requirements. And this concept has widely distributed in the manufacturing field and rapidly became as an innovative system, not only automobile assembly factories, but other field too.

In the museum, a commentary section on the concept of “Toyota Production System” is

In the museum, a commentary section on the concept of “Toyota Production System” is  provided as well as the examples of application in the factory operation for visitors. According to the explanation, we should see two basic concept pillars of “Toyota production system” in the concept, that is, “Automation” and “Just-in-time” in the manufacturing field. The commentary there extensively explains these with the elaborate illustration and with real adopted cases, such as what’s the scheme and mechanism are involved, what’s the origin of the thinking of Toyota Co., and how’s evolution and development have been actualized for the “method”.

provided as well as the examples of application in the factory operation for visitors. According to the explanation, we should see two basic concept pillars of “Toyota production system” in the concept, that is, “Automation” and “Just-in-time” in the manufacturing field. The commentary there extensively explains these with the elaborate illustration and with real adopted cases, such as what’s the scheme and mechanism are involved, what’s the origin of the thinking of Toyota Co., and how’s evolution and development have been actualized for the “method”.

For example, the unique messages that “if a problem occurs, the whole operation should be stopped immediately, and do not allowed to continue work before finding the reason of defects” (“Jido-ka” Self-decision automation), and the concept “Only at the time of necessity, the parts are supplied with necessary and enough volume in the process without stagnation” (“just in time”). And the practical examples to these concepts are also visually shown as actual mechanisms, like “string switch”, “Andon”, “Kanban”,

For example, the unique messages that “if a problem occurs, the whole operation should be stopped immediately, and do not allowed to continue work before finding the reason of defects” (“Jido-ka” Self-decision automation), and the concept “Only at the time of necessity, the parts are supplied with necessary and enough volume in the process without stagnation” (“just in time”). And the practical examples to these concepts are also visually shown as actual mechanisms, like “string switch”, “Andon”, “Kanban”,  “lot production”, etc. Although the concept itself looks quite simple, but it is well-thought and innovative way in the production process economically as well as technologically. It is really convincing when we see the explanation using practical examples in the site. Also, it was interesting to see the current challenging “Toyota’s Global Production Promotion Center (CPC) and its global Kaizen system too.

“lot production”, etc. Although the concept itself looks quite simple, but it is well-thought and innovative way in the production process economically as well as technologically. It is really convincing when we see the explanation using practical examples in the site. Also, it was interesting to see the current challenging “Toyota’s Global Production Promotion Center (CPC) and its global Kaizen system too.

♥ After visiting the automobile pavilion

I could just visit both Textile Museum and tour the Automobile Museum this time. in this tour, I really could recognized that automobile industry is how mighty broad and integrated industry, and could broaden my knowledge a bit about complex automobile technology. And also I realized how Textile and Automobile industries have been evolved with experiencing in the long period of time. And I noticed as well that the Japanese automobile industry had initially started just

I could just visit both Textile Museum and tour the Automobile Museum this time. in this tour, I really could recognized that automobile industry is how mighty broad and integrated industry, and could broaden my knowledge a bit about complex automobile technology. And also I realized how Textile and Automobile industries have been evolved with experiencing in the long period of time. And I noticed as well that the Japanese automobile industry had initially started just  from the imitation and acquisition of the technology from the US and Europe, but the catch-up speed was quite fast, especially Toyota Co. which has been accumulating its own technology through continuing efforts and own collaborative findings. And now, the company gains the first-class position in the automobile production in the global world. It was quite fruitful for me to be able to see the complexity of automobile technology through museum visit.

from the imitation and acquisition of the technology from the US and Europe, but the catch-up speed was quite fast, especially Toyota Co. which has been accumulating its own technology through continuing efforts and own collaborative findings. And now, the company gains the first-class position in the automobile production in the global world. It was quite fruitful for me to be able to see the complexity of automobile technology through museum visit.

However, it is commonly pointed these days that the future of automobile industry is looked unpredictable, in the meaning of environment problems, changing energy from gasoline to electric , surging autonomous vehicles movements, necessary safety measures, etc.

Under these circumstances, it is really interesting to see how automobile companies, particularly Toyota will move in the future. I’d like to know how Toyota will respond to these circumstances and how it will develop their technologies, production methods, and business strategies to adjust them in the future. In that means, this memorial visit has been a quite valuable for me.

Under these circumstances, it is really interesting to see how automobile companies, particularly Toyota will move in the future. I’d like to know how Toyota will respond to these circumstances and how it will develop their technologies, production methods, and business strategies to adjust them in the future. In that means, this memorial visit has been a quite valuable for me.

(end)

Reference:

- トヨタ産業技術記念館自動車館 HP:http://www.tcmit.org/exhibition/car/

- トヨタ産業技術記念館ガイドブック

- トヨタ自動車75年史 https://www.toyota.co.jp/jpn/company/history/75years/

- トヨタ自動車株式会社の社史編纂の歴史とアーカイブズ

- 「ものづくりの寓話」和田和夫 (名古屋出版会)

- 「ものづくり再発見―中部の産業遺跡探訪―」(アクネ技術センター刊)2000

- 「トヨタ生産方式」大野 耐一

- “The Toyota Way” J. K. Liker